Projects > Zambia > Zambia Schools

Zambia Schools

Zambia

Background

I arrived in Zambia in September 1970 and was given the job of completing the detail design, producing the working drawings and supervising the construction of three, large (600+ pupils) secondary boarding schools, all situated in the rural areas. One school was located at Chongwe, 30 miles from Lusaka, one was at Pemba, 150 miles from Lusaka and the third was at Chama, 550 miles from Lusaka.

Zambia is located in the tropics but as the majority of the country is at an altitude of around 1,000 to 1,500 metres it does not experience unduly high temperatures except in the valleys of the great rivers (Chama is located at the north end of the Luangwa valley and the first time that I visited the site it was over 40°C in the shade!). There is a wet season lasting from October to April and a dry season for the rest of the year. October is usually the hottest month and July the coldest. These climatic factors mean that buildings should be designed to keep the sun out of rooms and to provide good cross-ventilation in order to provide a comfortable environment without resorting to mechanical means. Glare from both the sky and the ground in the dry season are other factors that have to be designed for.

The World Bank was at that time implementing a large secondary school renovation and construction programme (approximately 120 schools) which was being managed by a Norwegian firm of consultants. The approach that they took was, for the time and place, very high-tech with the schools being constructed in the main of pre-fabricated fibre-cement components assembled on site on concrete floor slabs. The documentation system they used was also very new using CI-SfB coding, something that had never been used in Zambia before and which resulted in a multitude of drawings and other contract documents. The end result was that the programme took a very long time to complete and a few contractors went bankrupt due to the fact that they did not understand the documentation.

Our firm was given three schools that the government wanted built but which the World Bank had refused to fund. We therefore had to work to a very tight budget and keep costs as low as possible while at the same time ensuring that the schools would be simple to construct in remote locations (the contractor who eventually won the Chama school contract was based in the Copperbelt which gave him a 1,800 mile round trip to the school site and back to his base!).

Design of the Schools

Zambia is a land-locked country and at that time the only locally available building materials at that time were aggregates, bricks, cement and locally produced fibre-cement roof sheets. There was no local timber and all other building materials had to be imported by road from either Dar-es-Salaam or South Africa at great cost. Our approach therefore was to use traditional construction methods and local materials as much as possible, rationalised in order simplify construction in remote areas. The floors were of minimum thickness concrete slabs reinforced with mesh and with sand-cement screeds as a finish; the walls were of either local brick or sand-crete blocks manufactured on site reinforced with brick-force in the joints and the windows were louvres to give maximum cross-ventilation at a reasonable cost.

The main problem we had to resolve was how to construct the roofs. These had to be simple and economic to construct as well as being easy to transport given the long distances to two of the sites. They had also to be functional in that, as well as providing protection to the buildings from the elements, they had to provide protection from both the sun and the rain to walls and windows in order to maximise comfort in the rooms and reduce maintenance costs.

Analysis of the design brief had shown that the basic design module for the teaching spaces would be 8 metres with a 4 metre half-module where necessary for instance in service areas such as toilets, showers, stores, etc. The schools were therefore designed on a 4 metre module with structural walls at 4, 8, 12, etc metre centres.

As all structural timber had to be imported and was very expensive (and liable to attack from termites), it was decided to explore ways of using steel for the roof structure. Steel was at the time priced on weight and therefore if a very light structural system could be devised it was likely that this would be less expensive than using timber.

Working with our engineers and a local builder of truck bodies (who had the necessary bending presses for bending the steel sheets) we developed a very light, long-span lattice purlin which did away with the need for rafters. The purlins were constructed of pressed steel sections: the top member was an inverted ‘U’ and took the hook-bolt fixings of the roof sheets; the bottom member was a ‘top-hat’ section where the central ‘U’ shape provided space for electrical conduits and the ‘wings’ on either side supported the pressed metal ‘T’ sections that in their turn supported the ceiling panels. The lattice members welded between the top and bottom sections were simple pressed steel ‘L’ sections. The lower member of the purlins also provided a fixing position for the top of the louvre units that were used for windows. The basic purlin was 4 metres long and these could be bolted together (through end plates) to form any length based on the 4 metre module. See sketch for details.

The purlins were spaced at 1.35 metre centres, the maximum possible for the fibre-cement roof sheets and a specially-made curved roof sheet was designed for use over the centre of the buildings. This made it possible to omit one central purlin reducing the overall roofing cost still further. See section.

Because the purlins were 30 centimetres deep and had an open lattice framework web, this meant that the roof space could be used for services and could also be ventilated which helped to reduce the temperature in the rooms. Large roof overhangs (1.5 metres deep) were provided in order to keep the sun out of rooms from 8 am until 4 pm and to reduce glare from the sky and the external purlins were supported on projecting walls on the 4/8 metre module. See section.

The school buildings were designed as standard buildings and consisted of: a 3-classroom building; an arts and crafts building; two laboratory buildings; a library; a metal workshop; a wood workshop; a social studies building; an agricultural workshop; a medical building; a staff room; an assembly/dining hall/kitchen and dormitories. For the school at Chama which was very remote, we also designed and built staff houses.

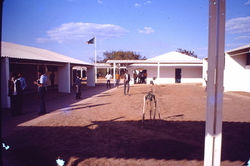

The layouts of all three schools were similar and were based on a ‘pavilion’ layout (which I discussed in an earlier post) that gave flexibility in the layout, allowed plenty of space between buildings, allowed for differences in level across the sites and also allowed for future expansion. All buildings were oriented to face north/south in order to reduce solar penetration into rooms as much as possible and all buildings were single-banked in order to maximise cross-ventilation.

A series of three or four covered ways running north/south linked all of the buildings and these routes also carried services such as water, electricity and the main storm-drains. All of the teaching buildings had front verandas that were linked to the covered ways and gave access to the various teaching rooms and the dormitories had direct access from the covered ways.

The schools were zoned with dormitories at one end and teaching spaces at the other with the assembly/dining hall and an external ‘school square’ in the middle of the school. The noisy teaching buildings such as the workshops were placed at the outside of the teaching zone.

Conclusions

This was my first project in Africa and I had to learn a lot very quickly. I had very good mentors in the persons of the two partners in the firm who had both lived and worked in southern Africa for a long time. I was also lucky to have three experienced and knowledgeable contractors from whom I learned a great deal about what you can and cannot do in situations where materials are expensive and skilled craftsmen are scarce.

This system of roof construction proved to be very economic, very simple to transport even to remote sites and very simple to erect; two men could easily lift an 8 metre long purlin into position. It also meant that there was no need for expensive concrete ring-beams or lintels and therefore the only concrete used in the buildings was for the strip foundations, the floor slabs and for filling the pockets in the tops of the walls around the ends of the purlins.

The very large roof overhangs protected walls and windows for the sun and rain and helped to keep the rooms cool and to reduce maintenance costs. The single-banked rooms with large opening louvre windows on both sides provided maximum cross-ventilation and kept the rooms cool. The ventilated roof spaces all helped keep the room temperatures down.

The pavilion layout with covered ways worked well and ensured that buildings were kept far enough apart to ensure minimum sound transfer between buildings and good ventilation for all buildings. It also enabled the provision of private courtyards for the service areas of the dormitories (which were for male and female students) and zoning of the noisy and quiet areas of the school.

Lessons Learned

All in all, I learned a great many lessons from designing and supervising the construction of the schools and with regard to school design these were that:

-

The whole school environment should be considered not just the classrooms;

-

The buildings should be accessible to all, appropriate in scale and attractive to the users;

-

The buildings should be arranged in the most economical way taking into account orientation, the slope of the site and the prevailing climate;

-

The layouts should incorporate courtyards and other external spaces for recreation, teaching and learning;

-

The layouts should allow for flexibility and future expansion and promote safety and security.

With regard to general design for buildings in tropical, developing countries the main lessons were that:

-

The designs should respond to the local climate, topography and any potential hazards (such as earthquakes, cyclones, etc) and most importantly,

-

The construction should be simple, cost-effective and aim to minimise maintenance costs.

The climate is a major influence affecting the comfort buildings in tropical countries and the layout and design of any building needs to reflect this. The key issues are that:

-

correct orientation of buildings in the tropics is essential if the sun is to be kept out of rooms and off main walls although in warm, humid climates it might be necessary to modify the orientation in order to face the buildings into the prevailing breeze;

-

elements of building design, such as roof overhangs, window openings and roof construction will affect ventilation, heat and light levels in the buildings and need to be properly considered, and

-

the use of planting to provide shade and help to keep buildings cool is often very cost effective and should not be overlooked. Trees can be planted at a safe distance to buildings to provide shade and climbing plants can be trained over verandas and roofs if these do not compromise the need to collect water from the roof.

With respect to construction, buildings should be simple to construct, respect local building traditions, use locally available materials and simple, locally understood construction techniques. They should also be designed to reduce maintenance costs as budgets for maintenance are not usually forthcoming in developed let alone developing countries. Anything that will reduce the need for or the cost of maintenance should therefore be considered even if it increases to some extent the capital cost of the building. It should also be understood that without a simple and economic roof design it is very difficult to construct low-cost buildings and the design of the roof also plays an important part in designing for climate in locations where it is important to keep the sun out of rooms and off walls. Large roof overhangs are also useful in keeping the rain off of walls and in reducing maintenance costs.

The specific lesson that I learned with regard to construction concerned the construction of the window walls which were either 4 metres or 8 metres long. In order to reduce costs we reduced the thickness of these walls to a minimum (either half a brick or a 10 cm block thick) and even though the walls were reinforced with ‘brick-force’ they cracked in the middle. Should have remembered my construction lectures: movement joints should be positioned at 6’ 0’’ (1.8 metre) centres for 6’’ (15 cm) thick walls; 9’0’’ centres (2.75 metres) for 9’’ (23 cm) thick walls, etc, etc!

The knowledge that I gained from this project has stood me in good stead over the years, has informed most of the projects that I have worked on since and continues to do so.

Project Gallery

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |